The accuracy of an assembly simulation is determined by how well the interactions between its parts are defined. At CAD FEA Solutions, we provide expert analysis of component interactions and connector elements, ensuring that your simulations reflect the true-to-life behaviour of complex mechanical systems. This detailed approach is critical for predicting performance, ensuring reliability, and optimising for efficiency.

Sophisticated Interaction Modelling

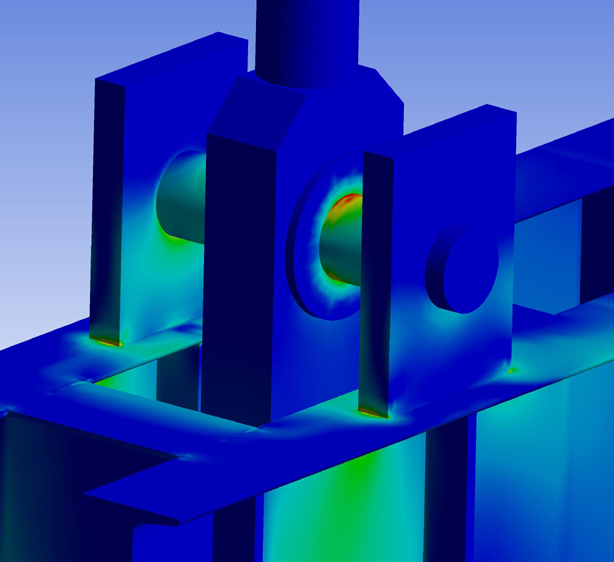

We provide detailed simulations of part-to-part contact, accurately modelling conditions such as friction, wear, pressure distribution, and load transfer. This is essential for understanding how components behave when pressed, sliding, or moving against each other.

Our expertise extends to simulating the interplay between multiple physical phenomena. This includes thermo-mechanical analysis, where thermal expansion affects contact pressure, and other coupled-field scenarios vital for predicting performance in complex operational environments.

High-Fidelity Connector Simulation

We accurately model a wide array of standard and custom connector elements, including bolts (with preload), welds, rivets, springs, and dampers. Correctly representing these elements is crucial for achieving a realistic simulation of any mechanical assembly.

We specialise in simulating the complex, non-linear behaviour of connectors under dynamic loads. This is essential for advanced applications such as vibration analysis, impact testing, and understanding how connections respond during time-varying events.

Integrated Workflow for Optimal Results

Our FEA solutions are designed for seamless integration with your CAD models. This ensures a cohesive and efficient workflow, allowing for rapid iteration between design modifications and performance validation.

By accurately analysing how parts interact and connect, we help you optimise designs for enhanced reliability, improved efficiency, and greater safety. This detailed analysis prevents issues like bolt failure, weld fatigue, and excessive wear, leading to a more robust final product.

Discuss Your Assembly's Unique Requirements

Ensure the performance of your mechanical systems with precise analysis. Contact us to discuss the specific interactions and connectors within your design.

CAD FEA Solutions: Engineering the Future with Precision and Innovation